About CO2 Sensor Accuracies

CO2 Monitoring & Enrichment Control Systems

By Kelvin Melton - August 15, 2023

About Sensor Accuracies

CO2 Monitoring & Enrichment Control Systems

Throughout this document, we will delve into the factors influencing these variations and why understanding these nuances is crucial for optimal performance and decision-making in your indoor agriculture applications.

Precision refers to the degree of consistency in the measurements provided by a sensor. It indicates how closely multiple readings taken by the same sensor, under identical conditions, are clustered around a specific value. A highly precise sensor will yield very similar readings for the same measurement, demonstrating low variability between measurements, while a less precise sensor may produce more widely spread readings, showing higher variability between measurements. Precision provides insight regarding the consistency and reliability of a sensor's data, highlighting how well it can reproduce the same measurement result when exposed to the same conditions repeatedly.

While precision is crucial for obtaining reliable data, it is essential to note that high precision does not necessarily guarantee high accuracy. A sensor can be precise (showing consistent results) without being accurate (yielding results close to the true value). Both accuracy and precision play vital roles in the overall reliability and usefulness of sensor data for decision-making, analysis, and control purposes.

These additional factors include sensitivity, resolution, offset, linearity, hysteresis, drift, temperature dependence, humidity dependence, pressure dependence, and response time. Each sensor has differing values for these factors, which can influence its performance in your operation. While it is not necessary to consider each of these factors when selecting sensors for specific applications, understanding that factors beyond accuracy and precision can impact sensor readings is essential. Universal Controls designs each control system by carefully balancing these factors, pricing, and application to choose the best sensors for your specific needs.

In the example above, when each sensor is calibrated correctly following the manufacturer's instructions, the CO2 value provided by the sensor (far right column) is valid, even if it does not read exactly 1,900 ppm. For the final sensor, UCSENS-IND-NEP, the manufacturer specifies an accuracy of "± 5% of reading, or ± 2% of scale." This means that the user must consider both accuracies and choose the higher (worse) value when determining if the sensor reading is accurate.

As sensors operate over time, the accuracy of their readings may decrease due to "drift." To correct readings that fall outside the acceptable accuracy range, sensors are either replaced or calibrated. Please see the section "Sensor Calibration" for more information on this topic.

The data sheets for each sensor shown above can be found at the end of this document.

It's important to note that the International Fire Code requires gas monitoring system sensors, like those used in carbon dioxide monitoring and enrichment, to be calibrated at installation and according to manufacturer specifications (Section 916.11 Inspection, testing, and sensor calibration). Universal Controls provides two-point calibratable sensors in our gas monitoring systems to meet strict safety requirements. However, for other systems, like environmental controls, different calibration requirements from manufacturers may be suitable.

The calibration of sensors is vital to ensure accurate and reliable readings in your facility, promoting safety and efficiency in your operations.

Go Back CO2 Monitoring & Enrichment Control Systems

Introduction

This guide is designed to provide valuable insights into the variations you may encounter when using multiple carbon dioxide (CO2) sensors from different manufacturers in the same room or facility. It is not uncommon for each sensor to display a different CO2 reading for the same CO2 level present in the environment. These variations in readings can range from minor to more pronounced. Despite these differences, it's essential to understand that each sensor's readings may still be considered accurate based on the manufacturer's stated accuracy specifications.Throughout this document, we will delve into the factors influencing these variations and why understanding these nuances is crucial for optimal performance and decision-making in your indoor agriculture applications.

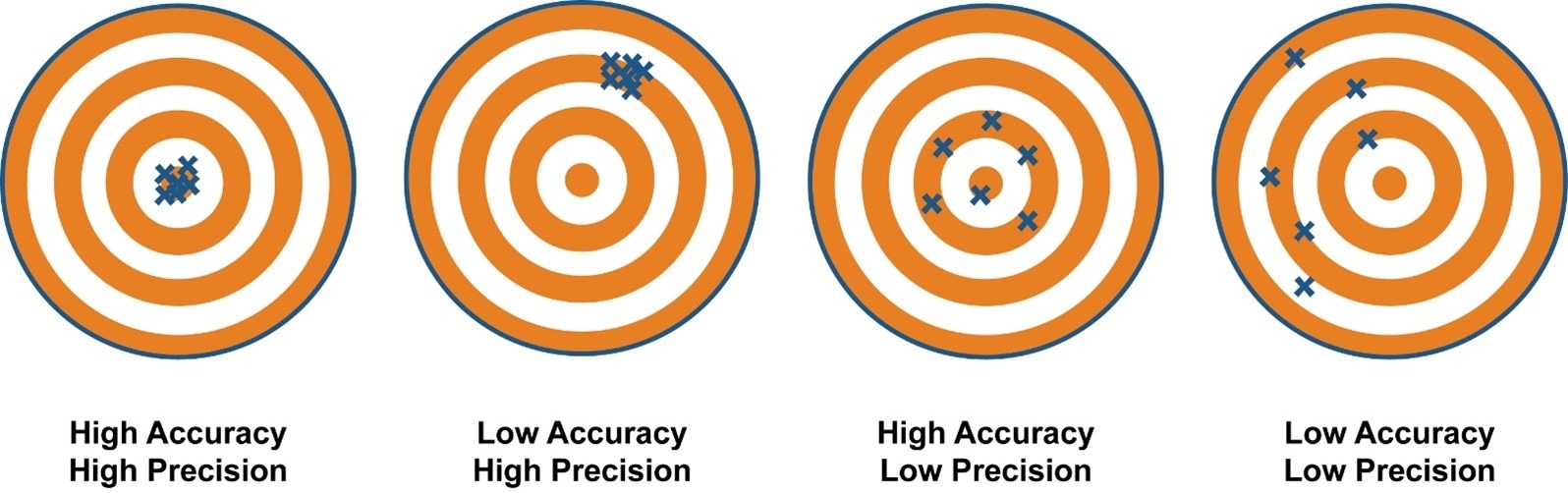

Accuracy & Precision

Accuracy is the degree of closeness between a measured value and the actual value of the parameter being measured. More simply, accuracy indicates how well a sensor can provide readings that are close to the real values of the quantity it is designed to detect. The accuracy of a sensor is typically expressed as a percentage or a specific value, indicating the maximum allowable deviation from the true value. A highly accurate sensor will provide readings that closely match the actual measurements, while a less accurate sensor may have greater discrepancies between its readings and the true values. Achieving and maintaining accuracy in sensor readings is crucial for making informed decisions, ensuring safety, and optimizing the performance of various systems and applications.Precision refers to the degree of consistency in the measurements provided by a sensor. It indicates how closely multiple readings taken by the same sensor, under identical conditions, are clustered around a specific value. A highly precise sensor will yield very similar readings for the same measurement, demonstrating low variability between measurements, while a less precise sensor may produce more widely spread readings, showing higher variability between measurements. Precision provides insight regarding the consistency and reliability of a sensor's data, highlighting how well it can reproduce the same measurement result when exposed to the same conditions repeatedly.

While precision is crucial for obtaining reliable data, it is essential to note that high precision does not necessarily guarantee high accuracy. A sensor can be precise (showing consistent results) without being accurate (yielding results close to the true value). Both accuracy and precision play vital roles in the overall reliability and usefulness of sensor data for decision-making, analysis, and control purposes.

Other Factors to Consider

For the sake of brevity, this guide will focus on informing users about accuracy and precision and how these two measurement fundamentals impact sensor readings. However, it's important to acknowledge that several other measurement fundamentals also affect sensor readings. Ensuring your sensors are of high quality, installed per manufacturer recommendations, and maintained accordingly is crucial.These additional factors include sensitivity, resolution, offset, linearity, hysteresis, drift, temperature dependence, humidity dependence, pressure dependence, and response time. Each sensor has differing values for these factors, which can influence its performance in your operation. While it is not necessary to consider each of these factors when selecting sensors for specific applications, understanding that factors beyond accuracy and precision can impact sensor readings is essential. Universal Controls designs each control system by carefully balancing these factors, pricing, and application to choose the best sensors for your specific needs.

Sensors Provided by Universal Controls

In the table below you will find the accuracy specifications for four (4) different CO2 sensors from different manufacturers. Every sensor manufacturer provides a list of specifications in what is called the “data sheet” for their equipment, which is where the range and accuracy data has been pulled.| SENSOR | RANGE (PPM) |

ACCURACY | EXAMPLE: CO2 LEVEL IN ROOM (PPM) | EXAMPLE: CO2 VALUE AT SENSOR (PPM) |

| UC-D5000 | 0 – 5,000 | ± 40 ppm ± 3% of reading | 1,900 | 1,803 – 1,997 |

| UCSENS-CMBO-IND | 0 – 5,000 | ± 50 ppm ± 3% of reading | 1,900 | 1,793 – 2,007 |

| UCSENS-HNDHLD | 0 - 10,000 | ± 2% of reading | 1,900 | 1,843 – 1,957 |

| UCSENS-IND-NEP | 0 – 5,000 | Greater of: ± 5% of reading, or ± 2% of scale | 1,900 | 1,805 – 1,995 |

In the example above, when each sensor is calibrated correctly following the manufacturer's instructions, the CO2 value provided by the sensor (far right column) is valid, even if it does not read exactly 1,900 ppm. For the final sensor, UCSENS-IND-NEP, the manufacturer specifies an accuracy of "± 5% of reading, or ± 2% of scale." This means that the user must consider both accuracies and choose the higher (worse) value when determining if the sensor reading is accurate.

As sensors operate over time, the accuracy of their readings may decrease due to "drift." To correct readings that fall outside the acceptable accuracy range, sensors are either replaced or calibrated. Please see the section "Sensor Calibration" for more information on this topic.

The data sheets for each sensor shown above can be found at the end of this document.

Sensor Calibration

When a sensor's readings consistently fall outside the acceptable range, it's time to perform maintenance. Calibration of a sensor involves exposing its sensing element to a known environment and adjusting its programming accordingly, typically through a two-point calibration. Universal Controls does not recommend 'automatic background calibration' (ABC) as it's not a true calibration method. Instead, ABC relies on statistical analysis, which can exaggerate drift in sensor readings over time.It's important to note that the International Fire Code requires gas monitoring system sensors, like those used in carbon dioxide monitoring and enrichment, to be calibrated at installation and according to manufacturer specifications (Section 916.11 Inspection, testing, and sensor calibration). Universal Controls provides two-point calibratable sensors in our gas monitoring systems to meet strict safety requirements. However, for other systems, like environmental controls, different calibration requirements from manufacturers may be suitable.

The calibration of sensors is vital to ensure accurate and reliable readings in your facility, promoting safety and efficiency in your operations.